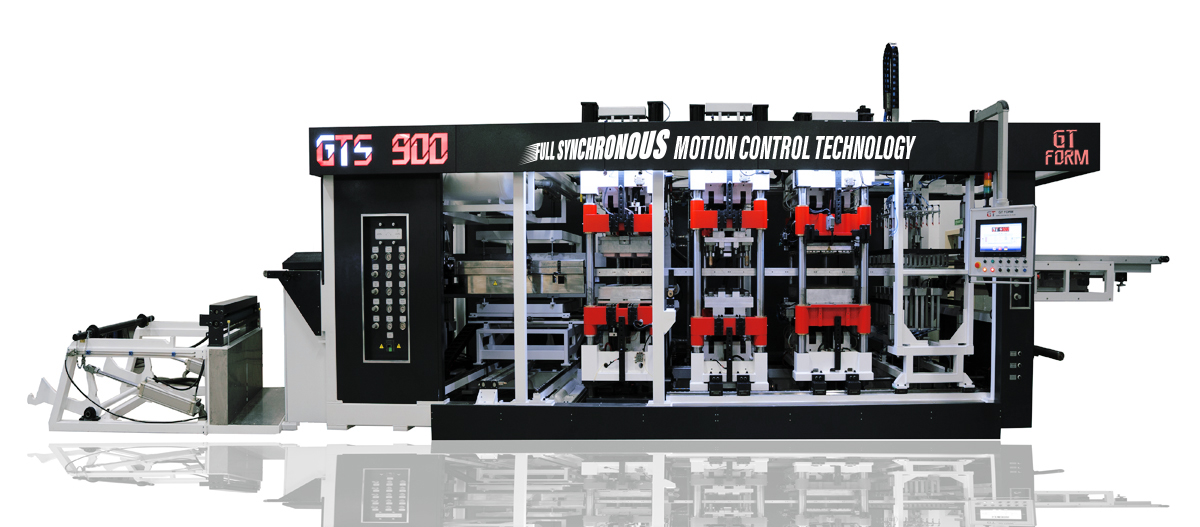

GTS 900 Steel Rule Cutting Machine

GTS 900 Steel Rule Cutting Machine General Specifications

- High performance, easy and safe operation with high techology.

- Rebust and solid machine body specially for high speed and non-stop production.

- Smart speed setting ability by touchscreen.

- Advanced heating system with izolated ceramic heater. NO NEED FOR PREHEATER.

- Quick tool changing and smart tool locking system.

- Reliable after sale service.

- Latest generation of software program and touch screen operating panel.

- High speed modem connection in order to facilitate after sale support.

- Induvidual lubrication inlets for each bearing.Technical Specifications

- Model : GTS 900

- Maximum tool size : 900 * 630 mm

- Pozitive stroke : 150 mm

- Negative stroke : 150 mm

- Production material : PP, Pet, PS, PVC, OPS

- Material thickness : 1.5 mm ( Maximum ) Pet – 2.0 mm PS, OPS, PVS, PP

- Lenght of the heater pan : 2300 mm

- Upper heater pan power : 97 Kw

- Lower heater pan power : 117 Kw

- Dry cycle : 80 cycle

- Vacuum pomp power : 3 kw

- Air requirement ( filtered air ) : 7 bar

- Electricity: 3 Phases 380 vollt 50 Hz

- 1. Feeding Unit

- Pneumatic roll lifting unit.

- Double roll lifting capacity.

- Sheet entrance ceramic side heaters for sheet transport.

- Nonstop unwinding system.

- 2. Chain & Chain Rails

- Omron servo motor chain pulling system from front side.

- 55 Hrc heat treatment steel channel for chain transport. ( Not Aluminum !!! )

- 42 Hrc custom manufacturing chain.

- Aluminum body with water cooling system.

- Dropsa Automatic lubrication for chain rails.

- Automatic sheet stretching ability.

- Motorised chain rails distance adjustment ability controlling by touchscreen.

- 3. Heaters

- Elstain brand izolated, energy saver H series ceramic heaters.

- 13 line standart ceramic heaters.

- 2360 x 935 mm dimensions heater trays. No need for pre heaters.

- Hig precission temperature controling with the horizontal and vertical cross heater design.

- Close timbered ceramic heaters with short gaps.

- 23 zones controlled upper pan.

- 13 zones controlled lower pan.

- Thermocouple PID temperature controoling system.

- Sheet melting laser sensors.

- Upper heater total power: 97 Kw standart.

- Lower heater total power: 117 Kw standart

- Anti-vibration heater trays lineers mowing design from bottom.

- 4. Forming Station

- 4 columns, each columns are 100 mm heavy duty shafts.

- Servo motor driven plug assist system.

- Servo motor driven, clamping force 60 ton.

- Max. Tool size 630mm x 900 mm.

- Max. Stroke up and down 150 mm.

- Motorised up and down height adjustment ability controlled by plc.

- Lineer system clamping frame design.

- Automatic lubrication for clamping frame.

- Induvidiual lubrication feeding for each beraing.

- Needle type heavy duty bearings.

- Flow rate controlling system for cooling water.

- Faster tool change, quick mould locking and automatic centering.

- Upper block take up system with support piston.

- 5. Punching Station

- 4 columns, each columns are 100 mm heavy duty shafts.

- Servo motor driven, clamping force 60 ton.

- Two movable platen ( upward and downward ) driven by Servo motors.

- Max. Stroke up and down 150 mm.

- Motorised high precission punching system for upper platen.

- Induvidiual lubrication feeding for each beraing.

- Needle type heavy duty bearings.

- Upper block take up system with support piston. ( to adjust paralelling between of the platens )

- 6. Cutting Station

- 4 columns, each columns are 100 mm heavy duty shafts.

- Servo motor driven, clamping force 60 ton.

- Two movable platen ( upward and downward ) driven by Servo motors.

- High precisse heating system for cutting knife controlling by touchscreen.

- Motorised X-Y position adjustment with lineer scale.

- Quick knife fixing.

- Cutting platens with minimal deflection to increase knife life.

- Induvidiual lubrication feeding for each beraing.

- Needle type heavy duty bearings.

- Upper block take up system with support piston. ( to adjust paralelling between of the platens )

- 7. Servo motorised Upward Stacking System

- -Lower cost with high efficiency.

- -A-B stacking.

- -High accuracy linner guides.

- 8. A-B-C Upward 3 Axess Robot Stacking System

- -High speed, high efficiency.

- -A-B-C Stacking.

- -Quick tool change.

- -Solid robot body.

- -Ina brand lineer systems.

- -Sew Eurodrive planet gearboxes.

- 9. Waste Roller Unit

- Sencronized waste roller with the tork control.

- Quich waste discharge system.

- Waste overload warning sensor.